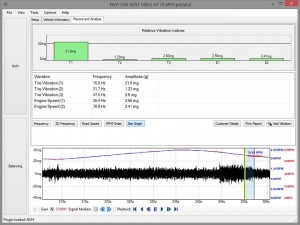

The PicoDiagnostics NVH Kit from Pico Technology is the cost-effective answer to the many NVH problems facing technicians today. Providing real-time diagnosis to the technician in the form of either: a bar graph, a frequency chart, a 3D frequency chart, RPM order or road speed view.

The cost-effective tool for real-time NVH diagnosis

Please note: The NVH kit from Pico Technology only works with our Automotive PicoScopes, and requires an unlock code in order to allow your PicoScope to work with the NVH software. This unlock key is limited to one PicoScope Automotive scope and is not transferable. Supported PicoScope models are 4425, 4225, 4423, 4223. RPM data may be taken from a J2534 Scan Tool or VCI (not included).

- Includes accelerometer and microphone

- Full screen, high-resolution results are presented clearly and accurately

- No external memory required – saves directly to laptop or PC

- Record up to 500 seconds of data

- Automatic analysis

- Detects multiple vehicle vibrations

- Customer report function

- Plugs into your Automotive PicoScope® (sold separately)

Overview

The PicoDiagnostics NVH Kit from Pico Technology is the cost-effective answer to the many NVH problems facing technicians today. Providing real-time diagnosis to the technician in the form of either: a bar graph, a frequency chart, a 3D frequency chart, RPM order or road speed view. The ability to start the recording before a road test, and play back the recording for analysis on your return, ensures that driver attention remains on the road. Saving the recordings couldn’t be simpler: much like our other automotive software you simply save the file to your laptop’s hard drive.

The PicoDiagnostics NVH kit makes use of the PicoScope 4000 Series Automotive oscilloscope, and comes complete with everything you need (J2534 Scantool or VCI not supplied). You can be sure that your investment in the PicoDiagnostics NVH kit will benefit your business without the need for further spending. If you already have a PicoScope 4000 Series Automotive oscilloscope, you’re halfway there.

Specifications

| Weight (interface / vibration sensor / microphone) | 120 g / 80 g / 20 g |

| Dimensions: Sensor interface (inc. BNCs) Microphone Magnet (inc. fitted grub screw) |

105 mm x 65 mm x 27 mm 43 mm x ø17 mm 12 mm x ø18 mm |

| Sensor extension lead length | 3 m |

| Battery (lithium primary cell) | CR123(A) 3 V (user-replaceable) |

| Battery life (shelf / vibration mode / microphone mode) | 10 years / 6 months / 2 months |

| Maximum measurable acceleration | ±5 g |

| Vibration frequency range (3 dB) | DC to 350 Hz |

| Shock survivability (accelerometer head) | 10,000 g |

| Temperature range (operating) accelerometer head |

–40 °C to 85 °C |

| Thread mounting (accelerometer) | ¼” x 28 UNF |

| Microphone sensitivity | 45 mV/Pa, nominal, at 1 kHz |

| EMC approvals | CE: Meets EN61326-1:2006 |

What’s in the pack?

A BNC cable connects the interface box to an Automotive PicoScope (sold separately). A USB cable connects your PicoScope to PC or laptop to run the PicoDiagnostics software. A Separate J2534 Scantool or VCI can be used to provide RPM data, but is not supplied.

Your PicoDiagnostics NVH Kit contains the following items:

- TA148 Single-output NVH interface unit

- TA096 Mounting magnet for accelerometer

- PA047 Carry case for NVH kit

- TA098 Cable: insulated BNC to insulated BNC 5 m

- TA143 MEMS accelerometer

- TA144 Microphone for NVH Kit

- TA145 Sensor extension cable for NVH interface unit

Typical Uses

Customer complaints surrounding noise/vibration are subjective at best and present technicians with a challenge before diagnosis and rectification begins. Applying the NVH kit to the vehicle will allow the technician to road-test the vehicle with the customer to obtain all vibration and noise levels. Once this valuable data has been collected it can be analysed and compared to previous captures or against donor vehicles. Often what is perceived by the customer to be a “problem” vibration is in fact a characteristic. Now you can present and compare objective data with test results from donor vehicles to reassure your customer all is OK. Alternatively comparing data may highlight a problem within the vehicle allowing the technician to proceed to a repair with confidence supported by measurements taken. Below are just a few of the typical scenarios where the NVH kit can save time and money:

- Cabin Vibrations at speed

- Engine vibrations throughout the entire rev range

- Clutch judder/vibration

- Transmission and bearing whine

- Auxiliary drive noise

- Brake judder

- Steering vibrations